Industries producing spray-dried powder whether it is chemicals, food additives, yeast and protein, coffee or dairy powder will need a bag filter to reach the increasing emission regulations. A positive side effect of limiting the emission is that the powders which were lost in the sky until now can be turned into yearly bottom-line numbers.

Powder loss from conventional cyclones on many spray dryers will typically be in the range of 0,5 % to 1,5 % (160-480 mg/Nm3) of the powder production - which is lost production and lost margin! With Simatek's many years of experience within the supply of hygienic CIP'able bag filters for food factories, we can help you recover this lost powder production.

To give you an idea of the value of recovered powder in the bag filter you can fill in your data in the below calculator and see the estimated yearly gain by installing a Simatek bag filter.

Calculate the value of the powder recovery here:

To give you an idea of the value of recovered powder in the bag filter you can fill in your data in the below calculator and see the estimated yearly gain by installing a Simatek bag filter.

What is your spray dryer powder capacity?

The powder output capacity of your spray dryer in kg per hour. This is the amount of dried powder your system produces, not the liquid feed rate.

What is the air capacity from your Spray Dryer?

The total volume of process air flowing from your spray dryer to the filtration system per hour. If you are unsure about the exact capacity, click the information icon and use the diagram for guidance.

What is the temperature of the process air

from the spray dryer?

The exhaust air temperature leaving your spray dryer.

This is typically measured at the outlet before the cyclone or bag filter.

What is the estimated powder emission from a cyclone?

The powder concentration in the air leaving your cyclone(s), measured in milligrams per normal cubic meter (mg/Nm³). This value indicates how much powder passes through the cyclone instead of being recovered.

What is your desired powder emission from a Simatek bag filter?

What is your production schedule?

Enter your typical production schedule. Consider planned maintenance, cleaning cycles (CIP), and seasonal variations.

What is the prime cost of the product?

The prime cost of your product refers only to the production cost, excluding packaging, transportation, marketing and profit margin.

Get your results

Fill in the form below to view your calculator results.

Based on your input we have calculated the possible value of powder recovery from the bag filter:

Basis for calculation

| Powder from the spray dryer | kg/h | 500 |

| Air capacity from spray dryer | kg/h | 25,000 |

| Temperature of process air | °C | 80 |

| Final Product price | per kg | 3.0 |

| Emission from Cyclone | mg/Nm³ | 250 |

| Corresponding to | % | 0.00 |

| Emission from Bag filter | mg/Nm³ | 5 |

| Corresponding to | % | 0.00 |

| Production hours per year | h/yr | 5,000 |

Recovery results from calculation

Estimated Powder Recovery in kg

Estimated Powder Recovery in value

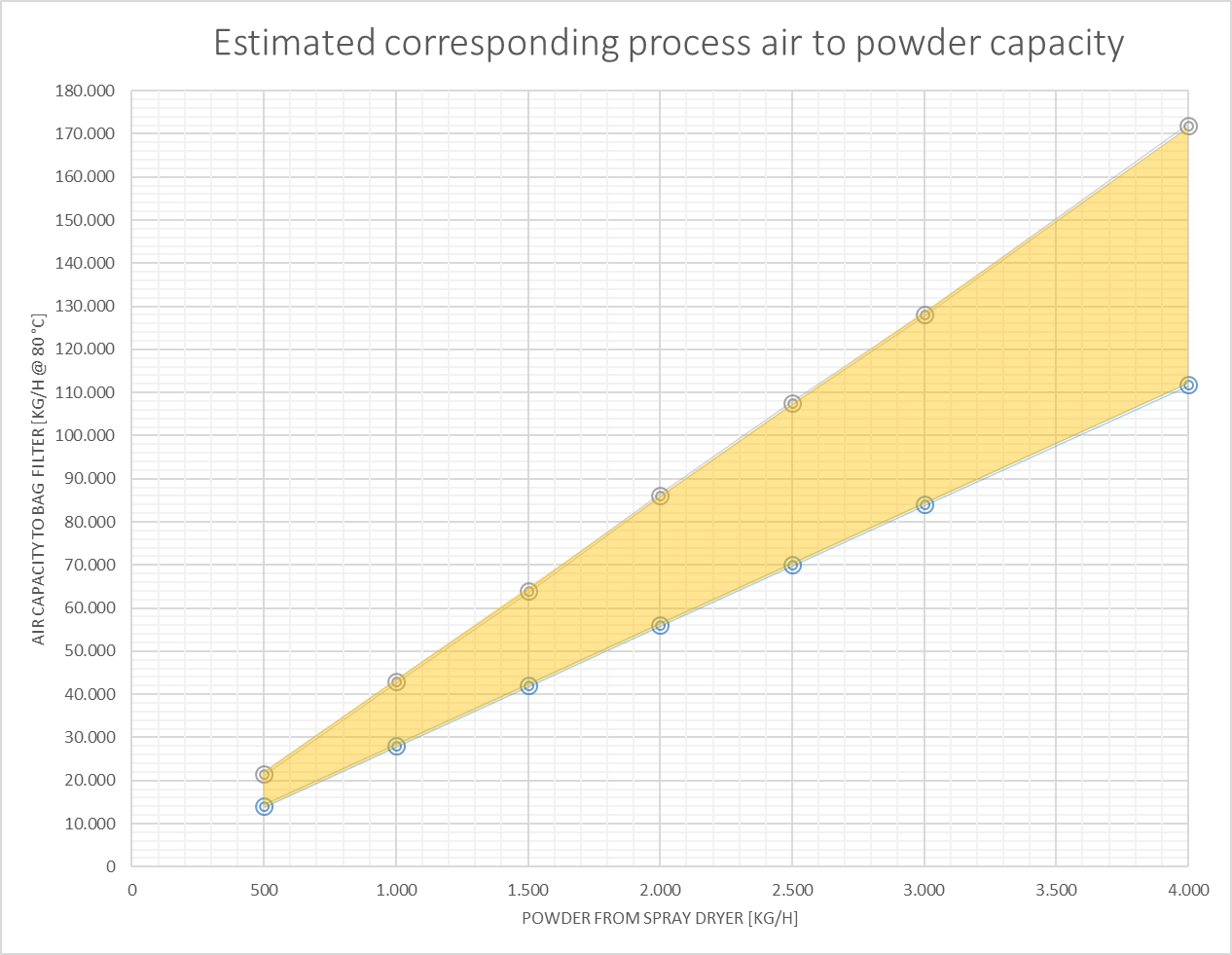

Estimated corresponding process air to powder capacity

Various factors is having an impact to the ratio between process air to the bag filter and final powder in the bag.

Following examples (but not limited to) can be mentioned:

- Whether the process air to the bag filter is from a single stage or multi stage spray dryer or from an agglomeration process, the ratio between process air and powder in the bag is fluctuating.

- The drying temperature, humidity of the drying air and exhaust air temperature to the bag filter.

- Total solids in the concentrate to the spray dryer versus the rest moisture in the final powder.

If the exact air capacity to the bag filter is not known the table shows an estimated range between the ratio between process air to the bag filter and powder in the bag.